With hundreds of builds to our name, Arkonik is the world leader in creating custom Land Rover Defenders for the most exacting clients. This is how we do it…

Our Process

Step by step

Concept

We pride ourselves on a collaborative approach. Whether you base your Arkonik Defender on one of our many featured builds, or start with a blank piece of paper, our expert team is on hand to advise and help steer you towards a truly unique, hand-crafted and personalized Land Rover reflecting your personality and our passion.

By carefully considering your intended use; be that an urban commute, overlanding or somewhere in between, we can ensure your Arkonik Defender is tailored to your needs. We never tire of hearing our clients’ own ideas and our engineers thrive on creativity, embracing any challenge presented to them. Once the spec is locked down, your excitement will heighten as your build slot transforms from an allocated number into its full rebirth programme.

Procurement

We begin by searching for authentic, structurally solid and correctly titled donor vehicles. We inherently know the best places to locate the perfect donors and our pursuit of these is never-ending. Only after an extensive appraisal has been carried out is a vehicle approved for purchase and can then join our inventory to be lovingly restored and reimagined.

Strip Down

Back at our base in South West England, your Land Rover is dismantled then the original steel frame is put on a custom jig. It is inspected carefully and re-aligned to factory specification, then shot-blasted and fitted with a new rear cross member. Finally, it is etch-primed and Raptor-coated for longevity and durability.

This thorough and proven evaluation of the stripped frame is a crucial part of the build, creating a firm foundation for our craftsmen to build upon.

Next, the Mechanical Team assembles all the drivetrain components. Firstly, the extensively rebuilt, Raptor-coated axles are coupled to the frame, then a brand new suspension system, all steering components, complete fuel system, brakes, bulkhead, A, B and C pillars, side seals and rear body tub are all fitted. The completely refurbished transmission, transfer box and engine are then reunited with the frame.

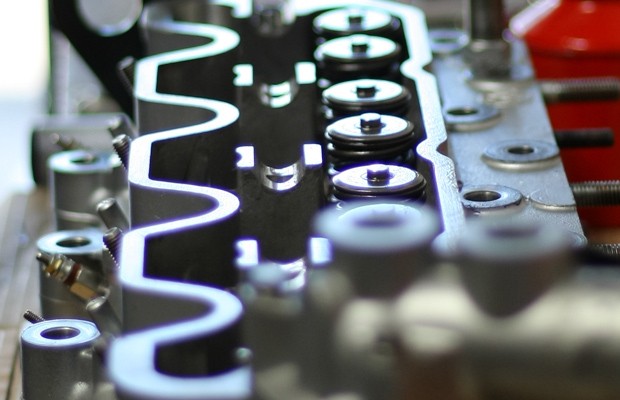

Engine

Our company has earned its enviable reputation using three choices of power-plant: the four-cylinder 200Tdi turbo diesel, 300Tdi turbo diesel and 3.5-litre V8 gasoline. These are very low-stressed engines, designed for a life of toil and minimum maintenance. Each engine is stripped to its last nut and bolt and every core component measured, pressure tested and machined back to original tolerances or replaced with new. If we’re not 100% happy, a period replacement of the correct quality is sourced and the process begins again. The end result is far better than it was when it left the original factory in Solihull. We utilise technological advancements with options which include replacing the V8’s carburettor with a four-barrel injector body, enabling us to programme and adjust the fuel and ignition mapping via an ECU. Between them, our team of in-house engine specialists have spent 50 years with their hands deep in Land Rover engines; we believe they are unrivalled in this area of expertise.

We are now also able to offer the GM® LS3 6.2L V8 Gasoline used in Chevrolet’s legendary Corvette; a modern power‑plant producing an impressive 430HP and providing a no-compromise approach to modern-day driveability.

Transmission

The Arkonik ‘leave no stone unturned’ attitude to refurbishment could not be more evident than when it comes to the vehicle’s five-speed, manual, ‘stick’ transmissions and transfer boxes. Nothing is retained except the outer casings and housings. We fit brand new British-made gearbox internals and uprated clutch hardware. Still, our gearbox team is forensic when it comes to the strip down, looking for any tell-tale signs that might point to weakness elsewhere along the powertrain.

We are also pleased to offer Automatic Transmission ranging from an original 4-speed to a high-tech, 6-speed variant, depending on your engine specification.

Bodywork

The iconic Defender silhouette begins to emerge as next we assemble your truck’s brand new bodywork. We have invested heavily in custom tooling enabling us to create our own bulkheads. We assemble new body panels, meticulously aligning them to deliver a better than factory finish.

Even brand new panels are not good enough for an Arkonik build! These are sanded back to bare metal, then meticulously prepared, primed, baked and inspected before the whole process is repeated for each and every coat. We have greatly improved upon the Defender’s original corrosion protection and water ingress from bumper to bumper. Only after careful inspection will it move onto the final stages of the paint process.

Paintwork

Historically, paint finish was Land Rover’s weak point. By now, it should be apparent that we not only address these flaws but our solutions go beyond comparison.

We prepare and paint each panel separately; roof, doors, fenders, hood and side panels are all treated individually, ensuring that when the vehicle is reassembled it has perfect alignment.

Our team of experts coat your vehicle with two or three coats of primer and one coat of etch primer before your chosen color is applied.

We can offer you an array of paint colors and finishes. From classic Coniston Green to striking Portofino Red. Virtually any color you desire can be created and paired with a variety of effects including; mica, metallic and Raptor finishes.

Assembly

Your vehicle is assembled in a methodical order allowing for numerous quality control checks and to minimize damage along the way. This process is expertly overseen by Craig who has been with Arkonik since it was founded.

To guarantee reliability and safety, our electrical engineers create a complete, custom wiring loom from scratch, using only the very best components available.

The interior refit begins with tailored sound-proofing and carpeting throughout. Now the personality of your Defender begins to reveal itself. Freshly painted panels are reassembled with brand new rubber seals. New windows, tires and wheels are then fitted to your Defender. The interior panels, roof lining, instrument gauges, door hardware and dashboard all follow.

Photography

Throughout the entire process, we will document and photograph your build with regular updates uploaded to your personal online portal.

Once completed, your Arkonik Defender is taken on location for a professional photoshoot. The high-resolution images are made available for you to keep; the perfect way for you to share your build with family and friends before meeting your Arkonik Defender in person.

Testing

Our testing procedure has been refined to a 250-mile programme split into five sessions; each designed to be tough enough to ensure that the finished Defender is bug-free and perfectly adjusted. Once it has passed vigorous water testing, gained VOSA MOT certification and the quality control team are 100% satisfied, the truck will receive its final valet including extensive underside protection.

Delivery

You will be shown every aspect of your Arkonik Defender by one of our handover specialists via video, or in person at our Charleston facility. This ensures that you are able to make the most of your investment and maximize the potential of your newly acquired automotive icon.

We are extremely proud of our ongoing relationships with Arkonik owners. You will be assigned a representative to deal with future questions and to assist with any inquiries about maintenance or upgrades. Now it is yours to cherish and enjoy with the reassurance of our comprehensive warranty and a lifetime commitment to you and your Defender.

Ready to start your journey?

Click on the link below and be inspired by our previous builds. Alternatively, dive straight in and build your own using our configurator.